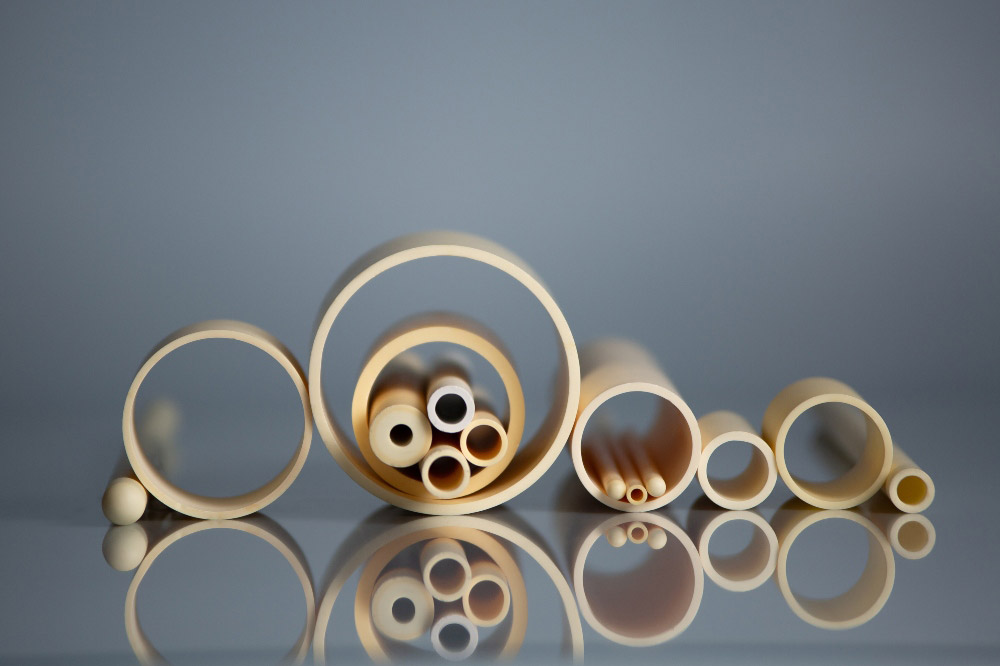

Alumina Tubes

View Our Alumina Tubing Product Page Links Below

What is an Alumina Tube?

When protection, resistance, and sturdiness are required, the first choice is alumina, or aluminum oxide. The strength and endurance of alumina has made it the first choice for conditions that require a highly resistant material that will not welt or decay in stressful conditions. LSP Industrial Ceramics is the number one producer of alumina custom made products, including our large selection of alumina ceramic tubing. Our high-quality manufacturing processes are known for producing a variety of alumina products and parts.

Alumina ceramic tubes have characteristics and features that make them ideal for a variety of conditions. This high-quality tubing has exceptional hardness, high resistance to chemicals, is long wearing, and is a perfect insulation material. Its varied properties have made it a staple for industries that require tubing capable of withstanding extreme temperatures.

The quality of an alumina tube depends on its purity. The higher the purity the more resistant it is. Tubing produced by LSP Ceramics has a purity factor of 99.5% or higher. Tubes can be shaped in a variety of diameters depending on the application. Our alumina tubes have high thermal conductivity and are capable of withstanding severe compression.

Since an alumina tube is dielectric, it is perfect for insulating electrical connections. The density of the ceramic material provides protection against incursions from gases or liquids. Due to the fact that it is resistant to wear and abrasion and maintains its stability at 1800o C, it is long lasting and dependable. Once installed, it can endure any hazardous or hostile conditions.

Uses of Alumina Tubes

A common use for an alumina tube is in industrial applications where high temperature resistance is required. Its durability has made it a popular component for many industries such as the manufacture of furnaces, heat exchangers, laser tubes, and corona treater tubing.

The extreme hardness, density, and strength of alumina ceramic tubing has made it a perfect choice for processes that involve mixed acids, bromine, halogens, and other aggressive or corrosive substances. In the heat exchanger industry, its qualities and characteristics make it able to absorb and dissipate heat to protect electrical coils or other equipment.

The outstanding durability of alumina ceramic tubing has made it an ideal material for the heating industry. Heaters manufactured with it are safer than electric ones since they reach a preset temperature and maintain it. The resistance to higher temperatures has made it an essential part of temperature measuring devices and temperature control equipment.

Benefits of Alumina Tubes

Compared to metals and polymers, an alumina tube is the first choice for extreme conditions. Its general properties and durability have made it an essential part of products that need to last but require low maintenance. This lasting quality has made it the number one choice for the production of products with a long life.

The other forms of tubing made from various polymers or metals may need frequent cleaning or replacement. Once alumina ceramic tubes are installed, they are guaranteed to last for years. An alumina tube’s resistance to chemicals and inability to conduct electricity makes it a perfect protective agent and insulator.