Zirconia Ceramic

Properties of Zirconia

Zirconium oxide (Zirconia) is an extremely tough ceramic with a hardness of >9 Mohs which makes it an excellent material for extreme wear, high temperature, and harsh environment applications. Zirconia ceramics have remarkable properties of strength, hardness, and wear resistance in addition to withstanding attack from molten metal, organic solvents, acids, and alkalis. They can also withstand high temperatures for long periods even under severe mechanical stress. Typical Applications include volatile chemical solutions transportation, jet and diesel engine components, containers for molten metals, high-speed cutting tools, high-wear components, transistor insulators, dental implants, bearing balls, pump seals, and ball valves. Contact us for more info!

| Density, ρ | g/cm3 | 6.04 |

| Water Absorption | % @ room temperature (R.T.) | 0 |

| Hardness | Mohs | 6.5 |

| Hardness | Knoop (kg/mm2) | 1600 |

| Compressive Strength | MPa @ R.T. | 2500 |

| Fracture Toughness, KIc | MPa x m1/2 | 13 |

| Max. Use Temperature (in air) | ºC | 500 |

| Thermal Shock Resistance | ∆T (ºC) | 280-360 |

| Thermal Conductivity | W/m-K @ R.T. | 2.7 |

| Coefficient of Linear Thermal Expansion, αl | µm/m-ºC (~25ºC through ±1000ºC) | 11 |

| Dielectric Constant 1 MHz @ R.T. ASTM D150 26 @ 100kHz | 1 MHz @ R.T. | 26 @ 100kHz |

| Dielectric Strength | kV/mm | 9 |

| Electrical Resistivity | Ωcm @ R.T. | >104 |

What Industries Use Zirconia Ceramics from LSP Industrial Ceramics, Inc.?

Zirconia ceramics, known for their exceptional strength, toughness, and wear resistance, are a cornerstone of advanced technical ceramics. At LSP Industrial Ceramics, Inc., we specialize in providing high-performance zirconia ceramic solutions tailored to meet the rigorous demands of various industries. With a hardness exceeding 9 Mohs, low thermal conductivity, and the ability to withstand harsh environments, zirconia ceramics are ideal for applications requiring durability and precision. Below, we explore the key industries that rely on LSP Industrial Ceramics’ zirconia ceramics for their innovative and high-performance needs.

1. Aerospace Industry

The aerospace industry demands materials that can endure extreme conditions, including high temperatures and mechanical stress. LSP Industrial Ceramics’ zirconia ceramics are used in components such as jet and diesel engine parts, where their ability to withstand thermal shock (up to 280–360°C temperature differential) and high temperatures (up to 500°C in air) ensures reliable performance. Zirconia’s toughness and low thermal conductivity make it ideal for insulating and structural components, contributing to the efficiency and safety of aerospace systems.

2. Medical and Dental Industry

Zirconia ceramics are widely utilized in the medical and dental fields due to their biocompatibility, hardness, and corrosion resistance. LSP Industrial Ceramics supplies zirconia for dental implants, which benefit from the material’s strength (compressive strength of 2500 MPa) and ability to resist oral environments without degrading. Zirconia’s smooth, high-tolerance finish also makes it suitable for surgical tools and prosthetic components, ensuring precision and longevity in medical applications.

3. Automotive Industry

In the automotive sector, zirconia ceramics from LSP Industrial Ceramics are employed in high-wear components and sensors. Their exceptional wear resistance and ability to withstand attack from acids, alkalis, and organic solvents make them ideal for parts exposed to harsh conditions, such as fuel system components and exhaust sensors. Zirconia’s thermal stability also supports its use in engine components, enhancing durability and performance in demanding automotive environments.

4. Industrial Manufacturing and Processing

Zirconia ceramics are a preferred choice in industrial manufacturing for applications involving extreme wear and high temperatures. LSP Industrial Ceramics provides zirconia for high-speed cutting tools, pump seals, and ball valves, which benefit from the material’s hardness (Knoop 1600 kg/mm²) and fracture toughness (13 MPa·m¹/²). These properties ensure long-lasting performance in abrasive environments, such as those found in mineral processing, chemical handling, and molten metal transport, reducing maintenance costs and downtime.

5. Electronics and Semiconductor Industry

The electronics and semiconductor industries rely on zirconia ceramics for their excellent electrical insulation properties (dielectric strength of 9 kV/mm and resistivity Greater Than 10⁴ Ω·cm). LSP Industrial Ceramics supplies zirconia for transistor insulators and other components requiring high dielectric constants (26 at 1 MHz). The material’s ability to maintain performance under high temperatures and mechanical stress makes it ideal for precision parts in semiconductor manufacturing, ensuring reliability in high-tech applications.

6. Energy and Power Generation

Zirconia ceramics from LSP Industrial Ceramics are used in energy and power generation for components like containers for molten metals and high-temperature insulators. Their low thermal conductivity (2.7 W/m·K) and ability to withstand prolonged exposure to high temperatures make them suitable for power-generating equipment and thermal processing applications. Zirconia’s durability ensures consistent performance in harsh conditions, supporting efficient energy production.

7. Defense Industry

In the defense sector, zirconia ceramics are valued for their toughness and resistance to extreme environments. LSP Industrial Ceramics provides zirconia for applications such as bearing balls and high-wear components in military equipment. The material’s ability to resist corrosion from chemicals and maintain structural integrity under stress makes it ideal for defense applications requiring reliability and precision.

Why Choose LSP Industrial Ceramics for Zirconia Ceramics?

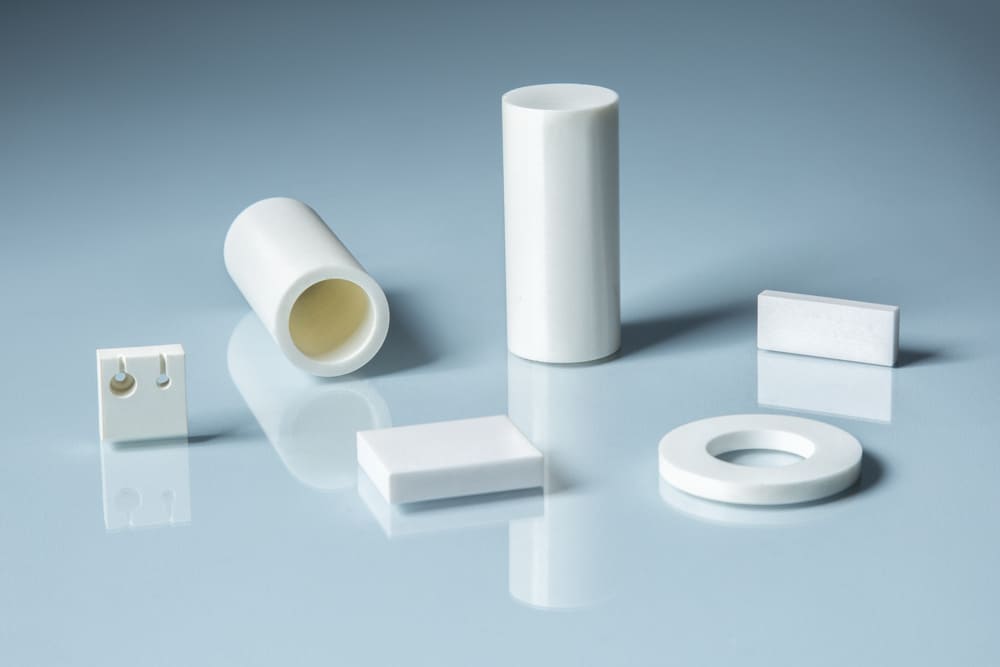

At LSP Industrial Ceramics, Inc., we leverage over 30 years of experience to deliver zirconia ceramic solutions that meet the specific needs of our customers. Our state-of-the-art manufacturing capabilities, including precision grinding, CNC machining, and custom fabrication, allow us to produce zirconia components like tubes, rods, and custom parts with exceptional accuracy. We offer a diverse inventory and rapid prototyping services, ensuring quick turnaround times and tailored solutions. Our commitment to quality and customer service ensures that our zirconia ceramics consistently meet or exceed industry standards, providing cost-efficient, high-performance solutions for demanding applications.

Conclusion

Zirconia ceramics from LSP Industrial Ceramics, Inc. are a critical material for industries requiring strength, durability, and resistance to extreme conditions. From aerospace and medical to automotive, industrial manufacturing, electronics, energy, and defense, our zirconia ceramics deliver unmatched performance in high-wear, high-temperature, and corrosive environments. With our expertise, advanced manufacturing capabilities, and dedication to customer satisfaction, LSP Industrial Ceramics is a trusted partner for businesses seeking reliable ceramic solutions. Contact us today at (609) 397-8330 or (609) 397-8341 to learn how our zirconia ceramics can enhance your next project.

About LSP Industrial Ceramics, Inc.

LSP Industrial Ceramics, Inc., based in Myrtle Beach, SC, is a leading manufacturer and distributor of industrial and technical ceramics, offering materials like alumina, zirconia, silicon nitride, and steatite. With over 40 years of experience, we provide custom solutions, including tubes, rods, and precision components, for industries such as aerospace, medical, and electronics. Our commitment to quality, innovation, and customer service ensures high-performance products tailored to your needs.